30+ Free Simple Failure Mode Effect Analysis Templates (MS Excel)

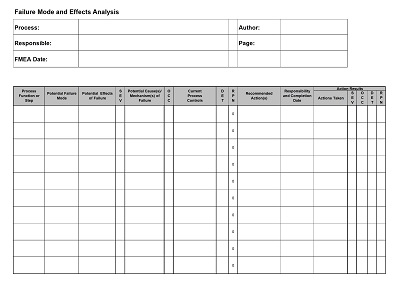

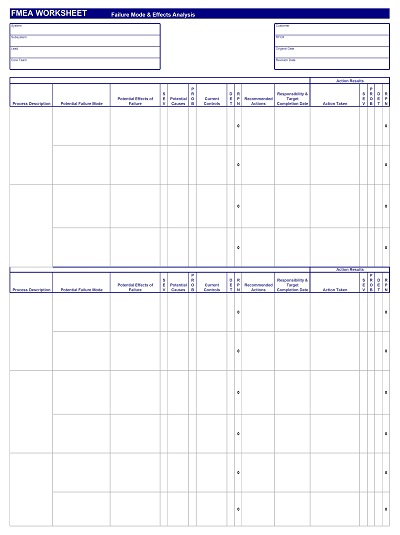

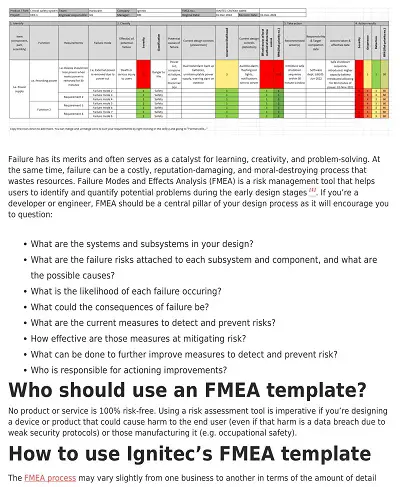

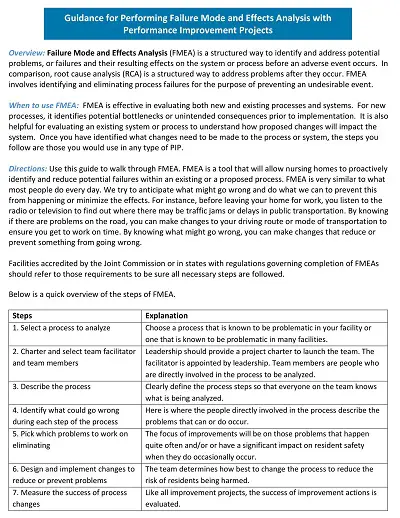

A Failure Mode Effect Analysis Template (FMEA) is a tool used to identify, review and mitigate the risks in a product or process. It provides an organized approach to help determine the potential failure modes of a system or product design, the effect of those failures, their causes, and how best to mitigate them. FMEA templates enable organizations to proactively address potential issues before they occur, allowing for more efficient production with fewer mistakes.

Table of Contents

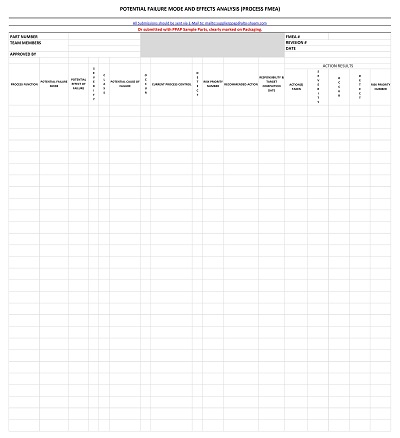

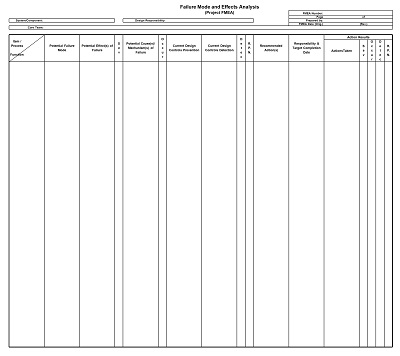

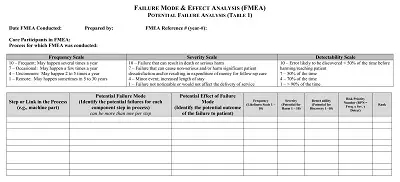

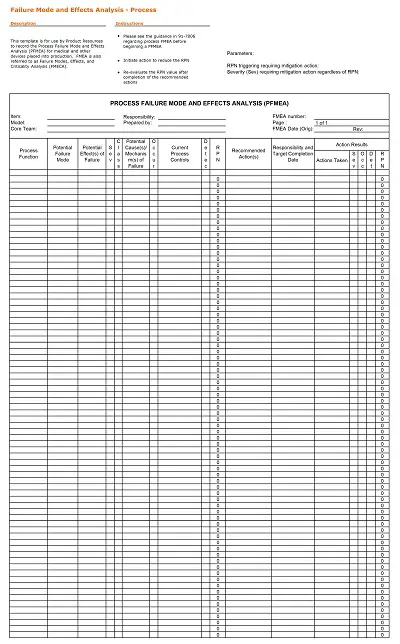

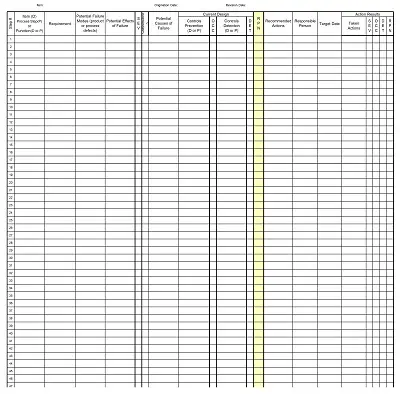

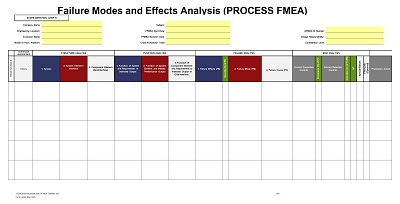

The template is composed of three main columns that detail items such as possible failure mode and associated effects, the likelihood that the failure could occur, corrective action vectors which can reduce the risk, and more. By utilizing an FMEA template, organizations can take proactive steps toward safeguarding their products and processes from preventable errors.

Download Free Simple Failure Mode Effect Analysis Templates

Benefits of using Failure Mode Effect Analysis

Companies benefit in numerous ways from using Failure Mode Effect Analysis (FMEA). It is a risk management tool that enables organizations to understand the potential areas of failure, both in process and product, before launching products or services. A correctly executed FMEA study can help organizations reduce user error, identify potential problems early on, and even avoid recalls by proactively addressing product weaknesses.

Even further, employing FMEA allows organizations to take preventative action for their products, rather than relying solely on corrective ones after an issue occurs. Overall, the financial benefits from following an FMEA approach far exceed any effort expended in its execution.

Types of Failure Mode Effect Analysis

Failure Mode Effect Analysis (FMEA) is a powerful tool that enables organizations to identify potential risks and proactively develop effective strategies for preventing them. It has been used in various industries, including manufacturing, engineering, and healthcare, since the 1960s. Here are some different types of FMEA and explore how they can help improve organizational performance.

Design FMEA (DFMEA)

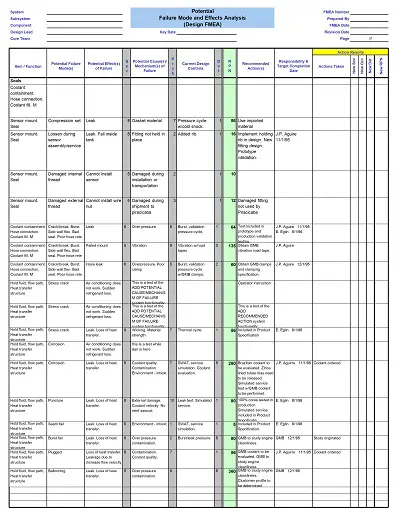

Design FMEA is used by product designers to anticipate potential risks throughout the design process. By identifying potential problems before production begins, manufacturers can avoid costly delays or recall due to unexpected issues with their products. DFMEAs are typically conducted at the beginning of product development and are updated as changes are made during the design phase. This allows designers to quickly identify new risks and strategize ways to address them before production begins.

Process FMEA (PFMEA)

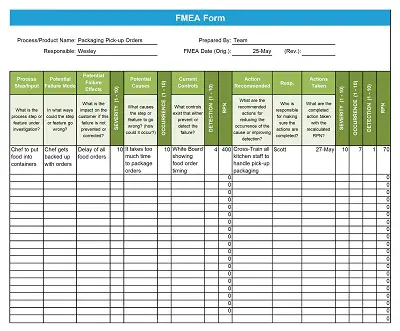

Process FMEAs are used by engineers to identify potential risks in existing processes. These analyses focus on identifying problems that may already exist within a system. By analyzing current processes, engineers can pinpoint areas where improvements should be made to maximize efficiency and reduce errors. PFMEAs look at both human factors and technical elements that could affect a process’s success rate.

Systems FMEA (SFMEA)

Systems FMEAs analyze all components of a system rather than just one aspect of it. This type of analysis allows organizations to understand how different elements interact with each other and how they could potentially impact one another if something goes wrong. SFMEAs provide an overview of an entire system and allow organizations to anticipate systemic risk before it becomes an issue.

Tips for Effective FMEA Team Collaboration

Team collaboration is key to achieving a successful Failure Mode and Effects Analysis (FMEA). Ideally, all members of the FMEA team should have backgrounds in engineering, production, service, and quality. By drawing on these different areas of knowledge during the process, issues can be identified more accurately. Effective communication and trust between team members are also essential elements for successful FMEA collaboration. Making sure everyone on the team takes the time to understand and respect different perspectives will help to minimize conflicts throughout the analysis.

Additionally, records of completed analyses must be routinely reviewed to ensure accuracy and up-to-date information. With these tips in mind, a well-coordinated FMEA team can identify opportunities for improvement and develop effective strategies to maintain quality standards across a company’s operations.

A Step-By-Step Guide to Creating a Failure Mode Effect Analysis Template

Have you ever been in a situation where something is not working as it should? Maybe your website isn’t functioning properly or your product isn’t meeting customer expectations. If so, then you understand the importance of having effective strategies in place to help identify and mitigate potential problems. One such strategy is called failure mode effect analysis (FMEA). This type of analysis helps to identify potential failure modes, the effects those failures may have on the system, and how likely those failures are to occur.

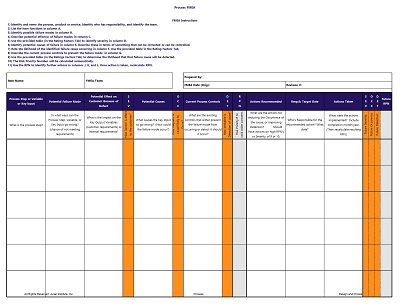

Identify Your System & Potential Failures

The first step in creating an FMEA template is to define which system you are analyzing and what potential failures could exist within it. For example, if you are creating a template for your website, one of the potential failures would be that visitors cannot access certain pages due to broken links or slow load times. By brainstorming all of the possible failures that could occur within your system, you create a comprehensive list of risks that can be addressed by the rest of your FMEA process.

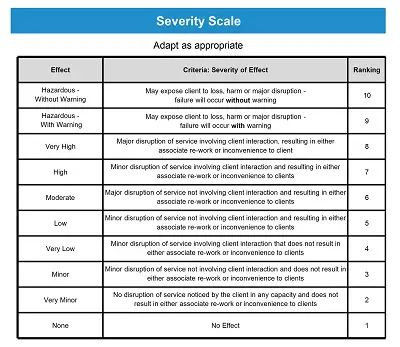

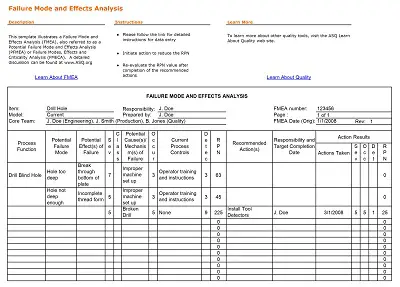

Assign Severity Scores

Once you have identified all of the potential failure modes within your system, assign each one a severity score based on its impact on customer experience. The severity score should reflect how serious an issue would be if it were to occur, higher scores indicate more serious issues that need to be prioritized over less severe ones. Depending on the type of business or industry you work in, there may be certain standards for assigning severity scores that need to be taken into consideration when determining individual scores for each failure mode.

Estimate Likelihood

The next step is estimating how likely each failure mode is to occur. Likelihood can be determined by measuring how frequently an issue has occurred in the past or predicting how often it might happen in the future based on current trends and data points. It’s important to note that likelihood can change over time, as technology evolves and customer preferences shift, some issues will become more or less likely than they were previously predicted to be.